In many vehicles, camshafts are operated by belt-driven systems, with a timing belt running over toothed gears. Maintaining precise timing is crucial to prevent engine performance issues or damage to vital components like pistons and valves. Adequate belt tension, neither too low nor too high, is essential to prevent belt slippage or breakage, which can lead to severe engine damage.

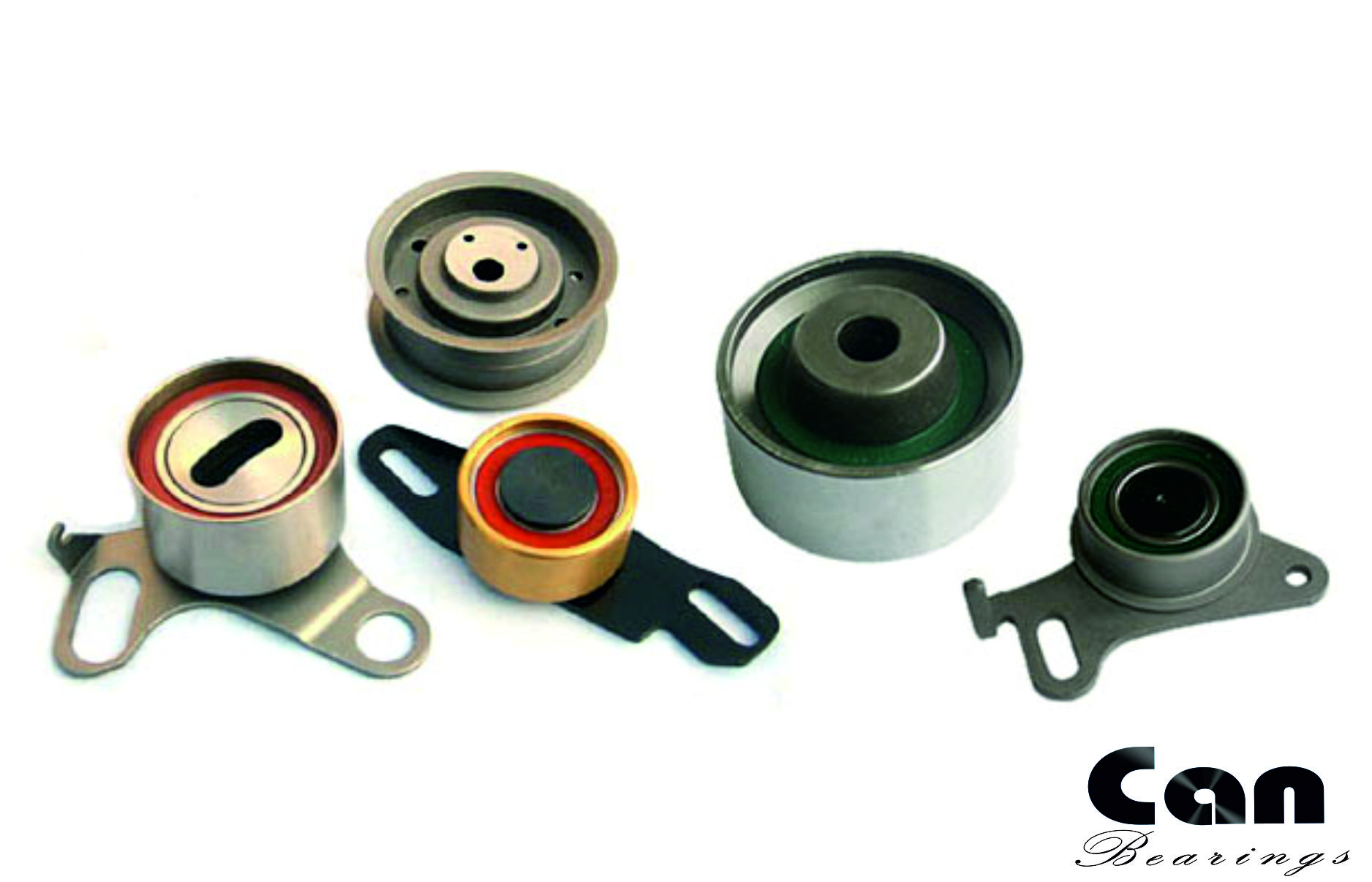

Tension in the timing belt is typically adjusted by a tensioner, consisting of a pulley mounted on a bearing and slider mechanism. Over time, tensioner components wear out, causing pulley surfaces to degrade and bearings to wear or seize. Noisy operation, vibration, and eventual belt failure may result if the tensioner is not replaced promptly.

It's recommended to replace the tensioner pulley when replacing the timing belt. Many opt for kits containing the belt, tensioner, and other pulleys for convenience, while others prefer to purchase components individually for customization or cost considerations. Regular maintenance and timely replacement of tensioner components are essential for reliable engine operation.