(CAN BEARINGS) has consistently believed in delivering quality bearing products & in an effort to do that, we constantly improve our process using the most up to date methodology and tools to deliver superior products to our clients. The list below shows some of the equipment we routinely use in maintaining superior quality of bearing products.

It is used for checking the distance between the rolling elements and the bearing races.

This imported testing instrument is used for checking the noise & vibration of Tapered, Cylindrical, Spherical roller bearings, Angular contact ball bearings and deep groove ball bearings. This instrument is used for upgrading the quality of CAN Bearings.

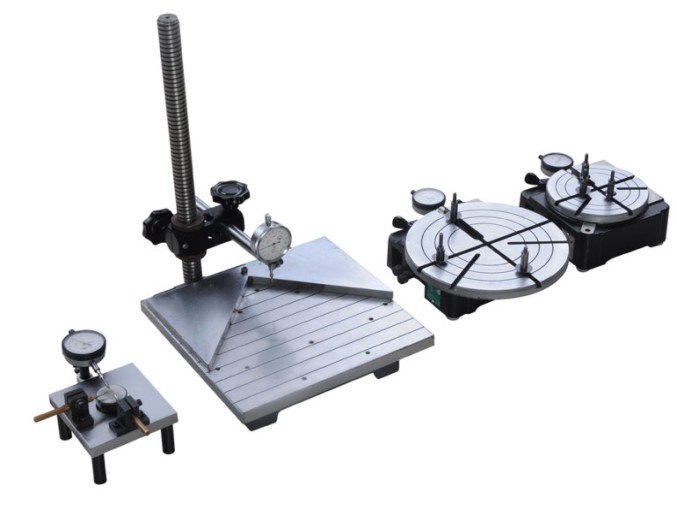

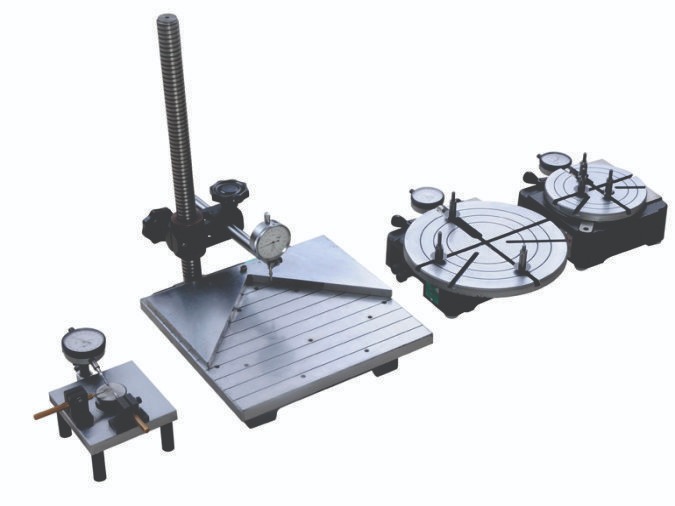

It is used for checking the roundness, squareness, concentricity and ovality of bearing and components, which ensure the running accuracy and long life of can.

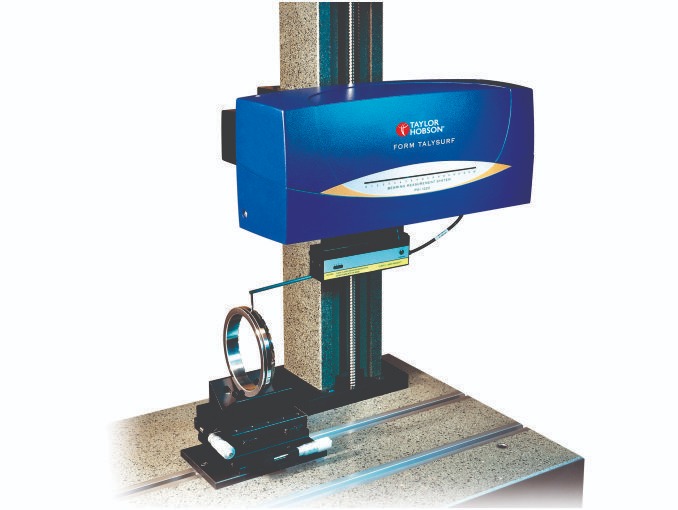

Surface finish measuring instrument is being used for checking the micro geometry, it evaluate parameters like Form geometry and surface finish of components. Also we are using this instrument for improving the quality and verifying our product with standards. It is also useful for R & D works as we can modify form of races & rollers to enhance performance of CAN Bearings.

Hardness is the property of a material that enables it to refer the resistance, bending, scratching and cutting of the bearing material. Bearing races and rollers are hardened and tempered at 58 to 68 HRC

It is used for checking the micro-structure of bearing components. By this equipment, we are maintaining consistent quality of micro-structure as per standard norms in prime raw material as well as in heat treated rings, roller & balls. It leads to improve the bearing performance of can.